How resistant are the Tiwal hulls?

Tiwal boats have been tried and tested under a wide variety of operating conditions. The tests include strong wind conditions, seas with short, long waves, launching in complicated places with rocks and UV resistance tests. Since 2021, we have evolved the manufacturing processes of our hulls to improve performance and durability.

Multi-layer construction

The hulls of Tiwal 2 and Tiwal 3 are reinforced in different places by several layers of fabric. The sides of the hulls are notably made more resistant by an overlay of yellow PVC. In addition, a wide band of reinforced PVC, used in rafting, protects the underside of the hulls from friction that may occur during launching and exiting. Since 2021, we have evolved the manufacturing processes of our hulls to improve performance and durability.

Robustness of inflatable hulls

If inflatable vehicles are used mainly for their lightness and ease of handling, they are also chosen for their robustness!

Firefighters, lifeboats and sailing schools use inflatable boats, because they withstand collisions and shocks better than conventional boats made of fiberglass or polyethylene. For example, rafting machines (inflatable) navigate easily through the pebbles in the rapids.

Try throwing a basketball (inflatable) against a wall, and do the same thing with a polyester object. Which one has the best result?

Still doubting? Check out this video… 😉

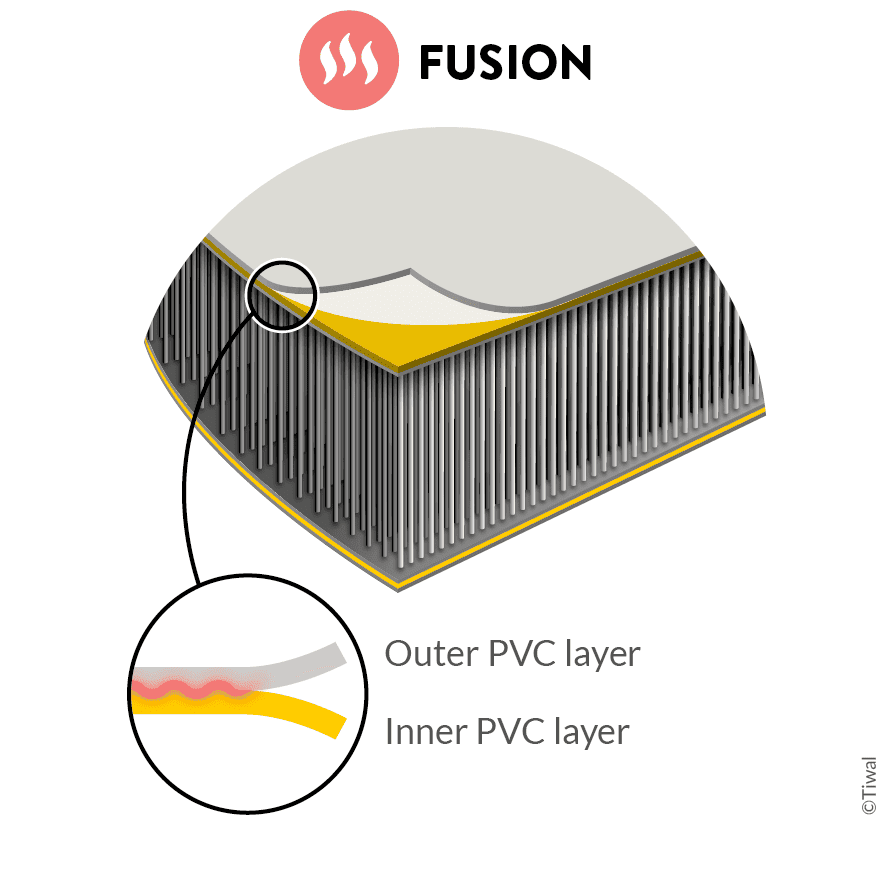

Fusion assembly

Tiwal’s Drop Stitch inflatable hulls benefit from Fusion technology since 2021. Let’s see how..

For great hull strength, Tiwal sailboats comprise 2 layers of PVC on the deck and on the hull.

Previously, these two layers were coated with glue before being joined together. Now, with Fusion technology, an ultrasonic process heats the surface of the two PVC layers to their melting point. They are then brought into contact under pressure. This welds the two membranes together to form one single membrane.

With this new technology, we go from a membrane-glue-membrane “sandwich” to a single membrane, creating one material, without glue.

This results in significant weight savings, in the order of 10 to 15% of the hull depending on the model.

Having removed the glue interface, which was slightly flexible, the two layers are now fused together as one. This makes the inflated hull even more rigid, offering better sailing qualities for the boat. As a result, Tiwal sailboats are even more responsive and faster.

Finally, the icing on the cake is that the hulls are even easier to roll up for storage or transport, as without the layer of glue, the deflated hull is more flexible.

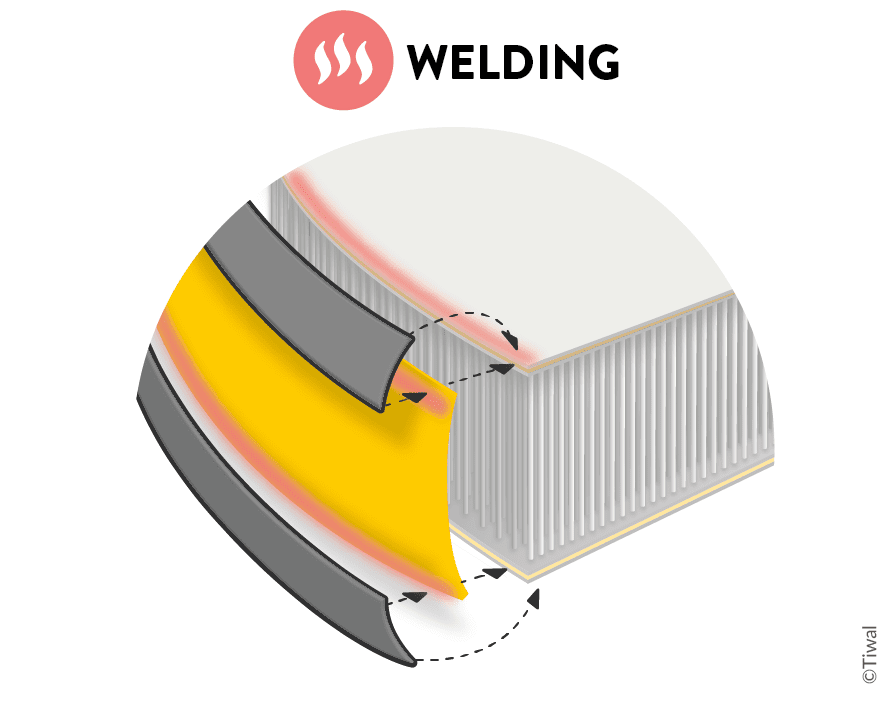

Thermo-welded joints

Also since 2021, the Drop Stitch watertight compartments of the Tiwal hulls are assembled by thermo-welding.

The initial hull assembly is done conventionally using glue. Then, a PVC joining strip is added to ensure the durability of the joint on all the watertight areas by a thermo-welding process.

From a technical standpoint, the surface of the PVC is brought to its melting temperature by a high-temperature air jet, and then the joining strip is put to the hull under pressure. The joining strip then becomes permanently welded and guarantees perfect watertightness of the assembly over time.

This process brings very high reliability and a superior longevity to the Drop Stitch inflatable hull.